The Leedy drum manufacturing company created some of the most beautifully crafted snare drums in history. Their drum factory workers and craftsmen concentrated on every minute detail, building the finest quality drums in the world. These drums are now coveted by collectors and players today as true masterpieces of the vintage snare drum kingdom.

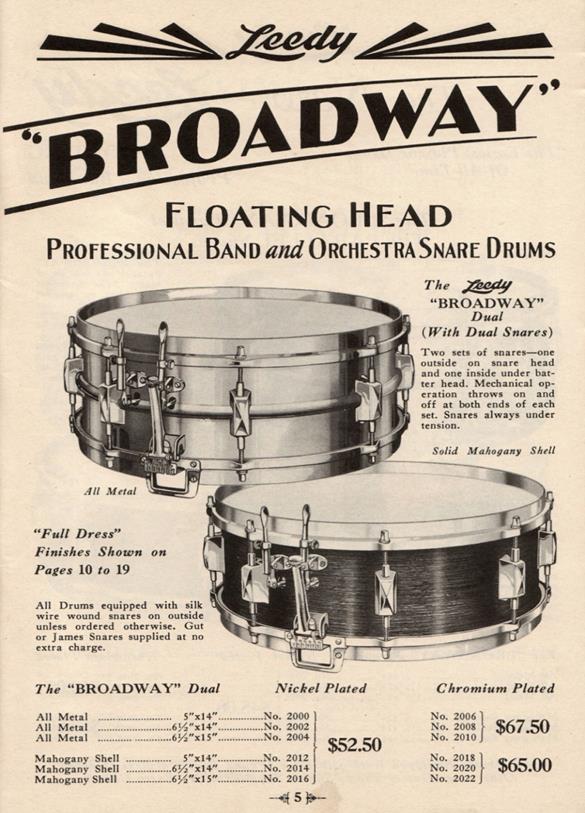

Leedy produced several great snare drum models between the early 1920s through the late 1940s. One of the most revered and popular snare drums was the Leedy "Broadway Standard" model. Leedy advertised this model to have a “floating drum shell” construction. These shells were crafted to an undersized dimension. For example, a 14” snare shell would be made approximately, 13”- 7/8”. This new design allowed for drum heads to be installed easily. The snare drum tuned up with ease and without choking out the beautiful sound dynamics. Many drum manufacturers of this time period constructed their shells exactly fourteen inches or actually oversized. One could spin a drum head on either side of the “Broadway” snare shell. In addition, Leedy cut their bearing edges with absolute quality and precision craftsmanship. This Broadway model was Leedy’s “workhorse” snare drum. Dedicated to the live music produced on “Broadway” shows of New York City, this model was first produced in the early 1930s. The very first model was made available with the center “X” or “box-lug” design. This lug was equipped with a self aligning insert. In the early 1920s Leedy was one of the very first drum companies to use a lug that had utilized a swivel nut. This invention allowed for smooth tension rod tightening without cross threading the lug. Previously and during this time period, almost all drum companies used their own version of the tube lug design.

Some of the “Broadway” snare models were offered in Leedy catalogs with various ornate finishes, such as the "Full Dress" model. These models came equipped with a choice of sparkling colored diamonds. The diamonds were glued and tacked on to your choice of finishes by the factory craftsman.

The consumers had several choice of finishes. The choice of wrap colors included several pearloids, sparkling pearls and solid lacquer finishes. The wood shells were made of a Solid 1-ply mahogany and solid 1-ply maple wood throughout the 1930s. Leedy offered the Broadway model in several sizes. The most popular sizes cataloged were 5"x14",5.5”×14”,6.5"x14", and 8"x14".

Interestingly, the sparkling pearls and pearl finished snare drums were almost always painted white on the inside of the shell. This was Leedy’s technique to protect the wood shell. However, the lacquered finished snare drums were left as natural wood on the inside of these shells. The most popular finishes were white marine pearl and black diamond pearl. In addition, the Leedy Broadway was offered in a metal shell model that could have been ordered in a choice of nickel, chromium or black nickel plating. Also, Leedy's “knobby gold” plating was offered on both wood and metal shell Broadway models. This process was a simulated gold plated surface that resembled real gold plating.

In 1939, Leedy introduced a new lug design to the Leedy Broadway snare line. The older "box lug" was discontinued. This new lug would be called the "beaver tail". Also in late 1939, Leedy would phase out the use of solid 1-ply wood shells. They would produce a 3-ply wood shell that would be made of maple-poplar-mahogany or maple-poplar-maple for the new Broadway models. This shell construction would be utilized on all of the Leedy wood shell models following the next ten years.

Let us take a look at a very interesting rare example of a 1949 Leedy Broadway Standard model. Example A: At first glance, this snare drum appears to be a typical “Broadway Standard” model resembling a cataloged prototype. The shell size is 5.5"x14". The finish is the venerable black diamond pearl. The hardware is all chrome plated. This includes sixteen of the Leedy Beavertail lugs, a Leedy 3-point strainer along with the extended butt-plate. Also, there is a Leedy single muffler installed. The sixteen strand snare wires are sixteen inches long and extended to accommodate the strainer system. The badge is clearly 1949.

The rare and unusual aspect of this drum is it was made with a solid one ply maple shell construction. The shell is natural wood, very thick and beautifully hand crafted. Also, notice the ink markings inside the shell. You can see the words Pearl along with the numbers 00.2000. A smudged 1949 date stamp is legible and an inked stamp serial style number on two panels of wood on the inside. All of these features are examples of deviations from stock models.

Example B: For comparison, here is the identical twin “Broadway Standard” snare drum. If you compare this snare shell to the solid 1-ply it is definitely much different. Notice, this drum has the 3-ply shell construction with a white painted interior. Also, this drum has all of the exact same hardware except it is nickel plated. The badge is also vintage 1949. Remember, by 1939 all solid shell construction was phased out so by 1949 these solid wood shells would have been completely discontinued and obsolete. Another interesting aspect is the placement of the factory Leedy single muffler. If we go back in time to the 1930s era, this is where Leedy placed their internal mufflers. The placement is on the opposite panel of the Badge. The first theory is that the Leedy factory had a few “leftover” raw shells from 1939 and wanted to utilize them. They would have built this drum using all necessary Broadway Standard hardware. A second theory is that Leedy still had a black diamond pearl shell that was originally made in around 1939. If this were the case, the shell may have been pre-drilled for the newer 1939 beavertail lugs that were used by Leedy up until 1949.These lugs obviously were used in both years. The same beaver tails would also be utilized on the later Leedy & Ludwig sixteen lug models. This particular solid shell may not have been painted because it was still in storage.

As time progressed these leftover solid maple shells were most likely kept on a back shelf. Also, these shells may have been forgotten or just overlooked, until Leedy’s craftsman needed to fill the order of the day. Also, by late 1949 Leedy was probably limiting production of new shells to gear down for their next transition, the merging of both Leedy & Ludwig drum companies. This changeover would take place in early 1950 and start production by 1951. This was a decision made by the owners of the C.G. Conn L.T.D. Music Company.

This “Broadway” snare drum is a beautiful example of Leedy’s wonderful solid shell craftsmanship. Fortunately, these Broadway models are still available in the vintage drum market. As a vintage drum enthusiast, it’s the thrill of the chase that may inspire you to find this exceptional model. You may just be the fortunate drummer to own one of these historical Broadway Standard snare drums.

The Leedy drum manufacturing company created some of the most beautifully crafted snare drums in history. Their drum factory workers and craftsmen concentrated on every minute detail, building the finest quality drums in the world. These drums are now coveted by collectors and players today as true masterpieces of the vintage snare drum kingdom.

Leedy produced several great snare drum models between the early 1920s through the late 1940s. One of the most revered and popular snare drums was the Leedy "Broadway Standard" model. Leedy advertised this model to have a “floating drum shell” construction. These shells were crafted to an undersized dimension. For example, a 14” snare shell would be made approximately, 13”- 7/8”. This new design allowed for drum heads to be installed easily. The snare drum tuned up with ease and without choking out the beautiful sound dynamics. Many drum manufacturers of this time period constructed their shells exactly fourteen inches or actually oversized. One could spin a drum head on either side of the “Broadway” snare shell. In addition, Leedy cut their bearing edges with absolute quality and precision craftsmanship. This Broadway model was Leedy’s “workhorse” snare drum. Dedicated to the live music produced on “Broadway” shows of New York City, this model was first produced in the early 1930s. The very first model was made available with the center “X” or “box-lug” design. This lug was equipped with a self aligning insert. In the early 1920s Leedy was one of the very first drum companies to use a lug that had utilized a swivel nut. This invention allowed for smooth tension rod tightening without cross threading the lug. Previously and during this time period, almost all drum companies used their own version of the tube lug design.

Some of the “Broadway” snare models were offered in Leedy catalogs with various ornate finishes, such as the "Full Dress" model. These models came equipped with a choice of sparkling colored diamonds. The diamonds were glued and tacked on to your choice of finishes by the factory craftsman.

The consumers had several choice of finishes. The choice of wrap colors included several pearloids, sparkling pearls and solid lacquer finishes. The wood shells were made of a Solid 1-ply mahogany and solid 1-ply maple wood throughout the 1930s. Leedy offered the Broadway model in several sizes. The most popular sizes cataloged were 5"x14",5.5”×14”,6.5"x14", and 8"x14".

Interestingly, the sparkling pearls and pearl finished snare drums were almost always painted white on the inside of the shell. This was Leedy’s technique to protect the wood shell. However, the lacquered finished snare drums were left as natural wood on the inside of these shells. The most popular finishes were white marine pearl and black diamond pearl. In addition, the Leedy Broadway was offered in a metal shell model that could have been ordered in a choice of nickel, chromium or black nickel plating. Also, Leedy's “knobby gold” plating was offered on both wood and metal shell Broadway models. This process was a simulated gold plated surface that resembled real gold plating.

In 1939, Leedy introduced a new lug design to the Leedy Broadway snare line. The older "box lug" was discontinued. This new lug would be called the "beaver tail". Also in late 1939, Leedy would phase out the use of solid 1-ply wood shells. They would produce a 3-ply wood shell that would be made of maple-poplar-mahogany or maple-poplar-maple for the new Broadway models. This shell construction would be utilized on all of the Leedy wood shell models following the next ten years.

Let us take a look at a very interesting, rare and unique example of a 1949 Leedy Broadway Standard model. Example A: At first glance, this snare drum appears to be a typical “Broadway Standard” model resembling a cataloged prototype. The shell size is 5.5"x14". The finish is the venerable black diamond pearl. The hardware is all chrome plated. This includes sixteen of the Leedy Beavertail lugs, a Leedy 3-point strainer along with the extended butt-plate. Also, there is a Leedy single muffler installed. The sixteen strand snare wires are sixteen inches long and extended to accommodate the strainer system. The badge is clearly 1949.

The rare and unusual aspect of this drum is it was made with a solid one ply maple shell construction. The shell is natural wood, very thick and beautifully hand crafted. Also, notice the ink markings inside the shell. You can see the words Pearl along with the numbers 00.2000. A smudged 1949 date stamp is legible and an inked stamp serial style number on two panels of wood on the inside. All of these features are examples of deviations from stock models.

Example B: For comparison, here is the identical twin “Broadway Standard” snare drum. If you compare this snare shell to the solid 1-ply it is definitely much different. Notice, this drum has the 3-ply shell construction with a white painted interior. Also, this drum has all of the exact same hardware except it is nickel plated. The badge is also vintage 1949. Remember, by 1939 all solid shell construction was phased out so by 1949 these solid wood shells would have been completely discontinued and obsolete. Another interesting aspect is the placement of the factory Leedy single muffler. If we go back in time to the 1930s era, this is where Leedy placed their internal mufflers. The placement is on the opposite panel of the Badge. The first theory is that the Leedy factory had a few “leftover” raw shells from 1939 and wanted to utilize them. They would have built this drum using all necessary Broadway Standard hardware. A second theory is that Leedy still had a black diamond pearl shell that was originally made in around 1939. If this were the case, the shell may have been predrilled for the newer 1939 beavertail lugs that were used by Leedy up until 1949.These lugs obviously were used in both years. The same beaver tails would also be utilized on the later Leedy & Ludwig sixteen lug models. This particular solid shell may not have been painted because it was still in storage.

As time progressed these leftover solid maple shells were most likely kept on a back shelf. Also, these shells may have been forgotten or just overlooked, until Leedy’s craftsman needed to fill the order of the day. Also, by late 1949 Leedy was probably limiting production of new shells to gear down for their next transition, the merging of both Leedy & Ludwig drum companies. This changeover would take place in early 1950 and start production by 1951. This was a decision made by the owners of the C.G. Conn L.T.D. Music Company.

This “Broadway” snare drum is a beautiful example of Leedy’s wonderful solid shell craftsmanship. Fortunately, these Broadway models are still available in the vintage drum market. As a vintage drum enthusiast, it’s the thrill of the chase that may inspire you to find this exceptional model. You may just be the fortunate drummer to own one of these historical Broadway Standard snare drums.